APPLICATIONS

These cables are designed for connections of exposed to extreme temperature changes. Often used in iron and steel manufacturing industry, aerospace industry, shipbuilding industry, lighting fixtures, ceramic, glass and cement factories.

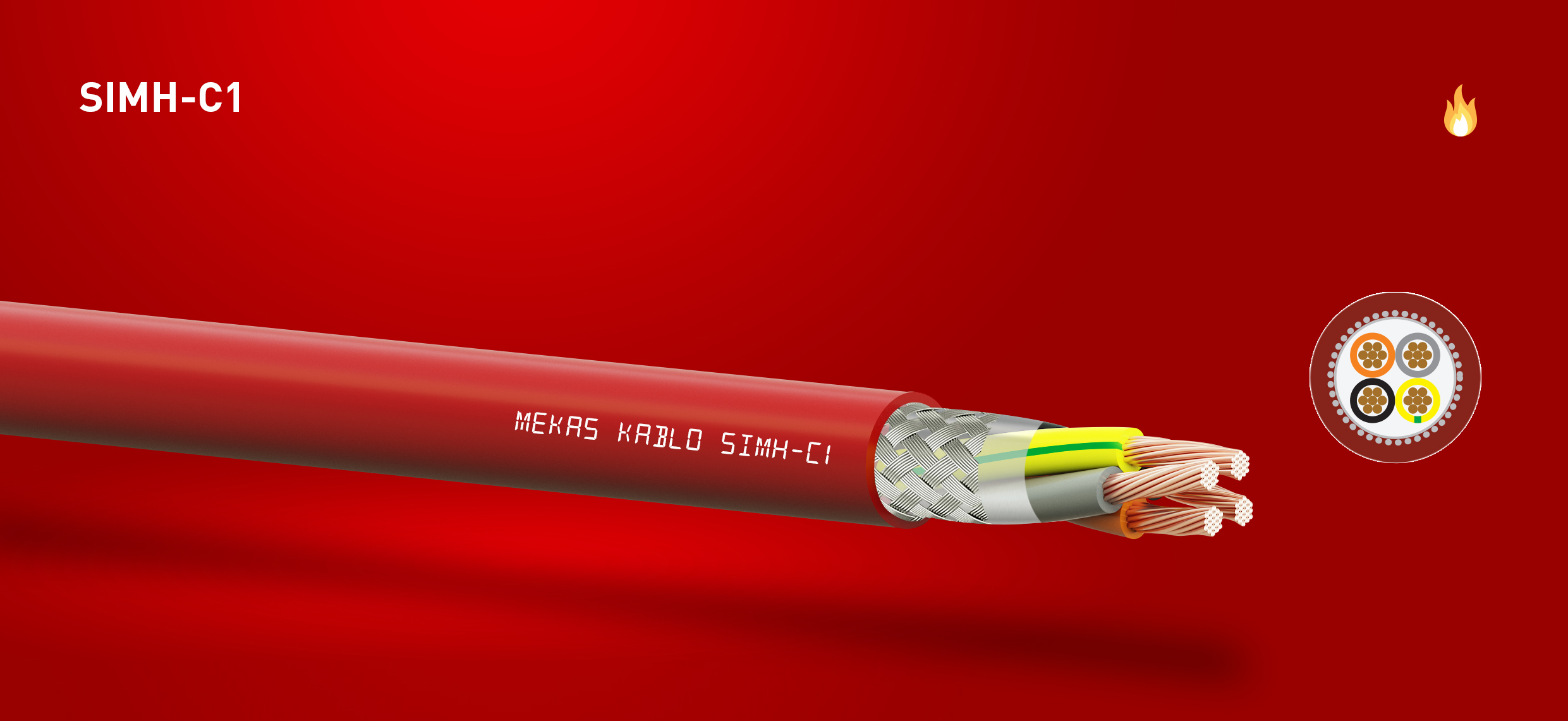

| CABLE CONSTRUCTION | |

|---|---|

| Conductor | Stranded Copper Wire Class 5 |

| Insulation | Silicone Compound |

| Insulation Color | DIN 47100 Color Coded |

| Twist | Twisting in Layers |

| Separator Tape | Pes Tape |

| Screen | Tinned Copper Wire Mesh |

| Outer Sheath | Silicone Compound |

| Product Types | SIMH-C1 |

| Packing | 500 – 1000 meters |

| ELECTRICAL PARAMETERS | |

|---|---|

| Working Temperature | – 60 ºC to +180 ºC |

| Bending Radius (min.) | 10 x D |

| Working Voltage | 300 / 500 V |

| Insulation Resistance | >200 MΩxkm |

| Conductor Resistance | 0.50 mm² : 39 Ω/km 0.75 mm² : 26 Ω/km 1.00 mm² : 19.50 Ω / km 1.50 mm² : 13.30 Ω / km 2.50 mm² : 7.98 Ω / km |

| Test Voltage | 0.50 mm² : 1200 V 0.75 mm² : 1200 V 1.00 mm² : 1200 V 1.50 mm² : 2500 V 2.50 mm² : 2500 V |

| FLAME RETARDANT TEST |

|---|

| IEC 60332-1-2 |

| VDE 0482-332-1-2 |

| EN 60332-1-2 |

| SMOKE DENSITY TEST |

|---|

| IEC 61034-2 |

| VDE 0482-1034-2 |

| EN 61034-2 |

| CORROSIVE GAS TEST |

|---|

| IEC 60754-2 |

| VDE 0482-754-2 |

| EN 60754-2 |